Maker Faire showcased a wide range of individuals who utilize the technologies available to create various types of projects. Some interfaces were specific to an audience who worked with the technology, but some could be used by the average joe. Overall, my Maker Faire experience introduced me to a lot of new technology and how people are creatively working towards improving the technology.

Key Glove, Jeff Rowberg The Key Glove project displays a new way to interact with technology without a keyboard. By putting on the Key Glove, a person can type using the motion sensors in the glove. This technology allows for the user to interact with their computer using the motion of their fingers. The Key Glove was created to be an accessory for technology as well as simplify interaction. It was designed with disabled users in mind. This is where I see Key Glove being the most successful. For the average person, the Key Glove may not be the most efficient way to do work. The interface seems difficult to work with because you would have to get used to what motions react to the key functions. It may end up being more frustrating to use the Key Glove than it would be to just use a keyboard.

However, for a person who is disabled, and is only able to type with one hand, this would be the perfect solution to their problems. The glove could also be a technology used in video games. As I read more about key glove online, Rowberg is successful in his design since he has clearly done research on his idea and what is also out there. He used what he has seen to combine technologies and develop the broad features of Key Glove.

AtFab: Open Source CNC Furniture A series of furniture that can be cut by a CNC router laser cutter or water jet, and assembled by locking the pieces together. AtFab struct my attention because I thought the design of their products were functions, visually pleasing, and resourceful. This interface brings together the technology of CNC and a laser cutter with the practicality of creating furniture for the home. AtFab recognizes that their furniture might not be perfect for everyone but it is for most.

I appreciate this idea because it shows that the technologies of a laser cutter or a CNC router can be used to create well-designed products for everyday life. Although initially developed to work with larger scale projects, AtFab proves that these technologies can successfully work for the average person (with the money, of course).

The perks of having this type of furniture would be that it can easily be moved, taken apart, stored, and then put back together. What makes AtFab successful and useful is the availability of their files online. The purchaser can use the files at home if they have the tools available, or they can order them to be cut. The only downfall is that not everyone has a CNC router or laser cutter at home. However, this project has a lot of potential for the future and since they are going to keep designing and customizing their products in the future, they will definitely find success.

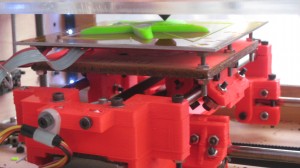

MakerBot Industries: 3D Printer Prior to the Maker Faire, I have never seen a 3D printer in action. I had no idea that it basically worked like a glue gun that melted down the plastic material to print layer by layer. There were many people there showcasing what they can do on their 3D printer, but I listened to what John Abella had to say about his. This was another opportunity where I saw that the 3D printer did not just have to be used to prototype projects, but was becoming affordable to be used in the home. Abella had a few models of objects he created on his 3D printer, but what was more interesting to me was how he uses the technology to fix things around his house. (He also created the card-stand that held his brochures!) This man was a hobbyist and enjoyed how much fun he could have with this product. There were also people at the Maker Faire who showed how the 3D printer could be used to extrude cookie dough and chocolate.

The technology behind a 3D printer gives possibilities to society, but what I would be hesitant about is purchasing one and not being able to understand the working mechanics. A person who would purchase a 3D printer would not just have to understand the working mechanics of the printer, but also the 3D modeling programs (AutoCAD, Rhino, etc) and how to use it. This type of interface will definitely be successful for those people who are prototyping projects. The price is fairly reasonable, but in the future, it will become even more affordable. The technology of a 3D printer definitely shows promise in aiding inventors and properly speeding up their process.